Production Line

Our main production process takes shape on our two modern and fully automated extrusion lines. We produce your aluminium profile with the highest quality and precision.

Our production capacity is 23.000 tons per year. With 1800T and 4000T Press, we can produce extruded aluminium profiles for different areas of use. With more than 3,000 fixed rotations of more than 3,000 molds, we have the ability to produce profiles ranging from 150 g to 21 kg/m.

| Profile Weight | 0.15 - 21 kg/m |

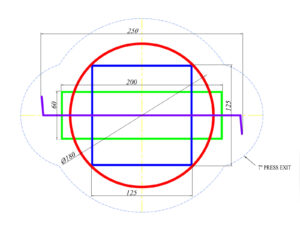

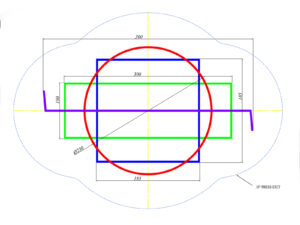

| Maximum Profile Width | 390mm |

| Max. Square Profile | 185mm x 185mm |

| Max. Rectangular Profile | 390mm x 60mm |

| Max. Pipe Profile | 230mm |

| Max. Filled Profile | 95mm |

| Max. Flat | 350mm x 20mm |

| Max. Profile Length | 14m |

| Alloy | 6060,6063, 6463, 6005, 6005A, 6061, 6082, 7XXX, 2XXX, 1XXX |

| Surface | Press, Anodizing, Powder Coating |

| Machining | Mechanical Process Cutting, Drilling, Turning, CNC machining, Bending, Press Drilling, Welding, Deburring, Assembly |

| PRESSES | SMS Press | Danieli Press |

|---|---|---|

|

|

|

| 18 MN | 40 MN | |

| Supplier | SMS | Danieli |

| Manufacturing Year | 2015 | 2021 |

| Model | Direct | Direct |

| Sleeve | 7” | 8”/10” |

| Billet Length (mm) | 350 - 1000 | 450 – 1600 |

| Max. Billet Weight | 67kg | 215kg |

| Billet Heating | Gas + Conical Heating | Gas + Conical Heating |

| Profile Cooling | Air | Air, Water, Spray, Misty |

| Max. Extrusion Length | 39m | 52m |

| Minumum Stretching Length | 8m | 10m |

| Max. Thermal Profile | 13m | 14m |

Shock Cooling System

One of the most important parameters for profiles used in the automotive industry (especially crash-box and front and rear bumper) is the cooling of the profiles during extrusion. Asen's new investment-Quench system can cool profiles with challenging shapes very quickly to achieve the desired mechanical properties.

- Air, water spray, fog 2-zone cooling and pressure can be adjusted separately

- Each nozzle line can be pressure controlled with proportional valves

- Cooling settings are recorded as profile-based prescription

- Each nozzle line can cool profiles with +/- 20° angle